1500W、2000W、3000W、6000W Galvanometer Fibre Laser Welding Machine

This equipment employs a galvanometer laser welding method, capable of welding metal materials such as stainless steel, copper, and aluminium alloys. It finds application in industries including medical components, automotive parts, and 3C electronics.

Products Categories

Get A Free Quote

Features of Galvo Laser Welding Machines

- When paired with fibre lasers (such as ring lasers or blue light lasers), it offers high electro-optical conversion efficiency, low energy consumption, and requires no maintenance.

- Utilising a scanning welding process with oscillating galvanometers, this method achieves rapid welding speeds and superior weld quality, producing stable, reliable and aesthetically pleasing welds.

- The machine adopts a multi-axis motion control mode ,to achieve diverse product welding.

- The machine stroke can be customised to suit welding requirements, and includes protective covers, dust extraction purifiers and other devices.

- Equipped with a high-definition CCD camera, the welding effect can be directly observed during the welding process.

- The equipment is easy to operate, has high processing accuracy, fast welding speed, and one-stop delivery.

Galvo Laser Welding Machine Parameters

| Machine Model | CM-WFG1500 | CM-WFG2000 | CM-WFG3000 | CM-WFG6000 |

| Laser Wavelength | 1080±5nm | |||

| Maximum output Power | 1500W | 2000W | 3000W | 6000W |

| Fibre length | 10m | |||

| Adjustable power range | 10-100% | |||

| Laser Modulation Frequency | 50KHZ | |||

| Laser Operating Mode | Continuous/Pulse | |||

| Spot Adjustment Range | 0.5-8mm | 1-15mm | ||

| Power Stability | ±1% | |||

| Cooling Method | water cooling | |||

| Positioning Method | Red light indicator | |||

| Welding material | Stainless steel, aluminium alloy, copper, galvanised sheet metal and other metallic materials | |||

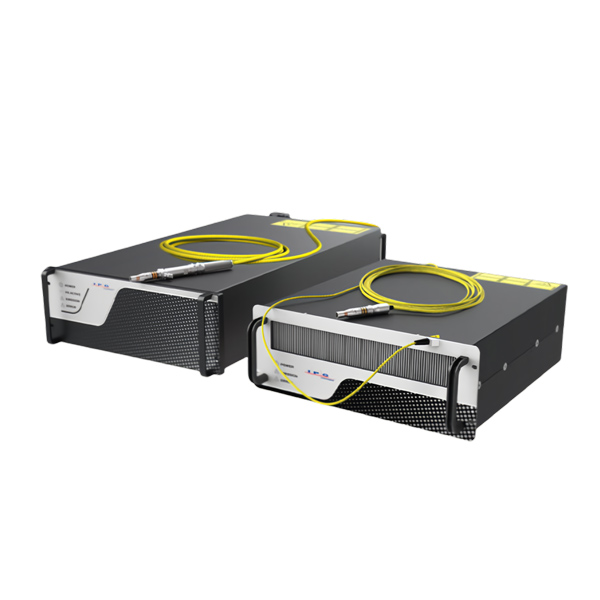

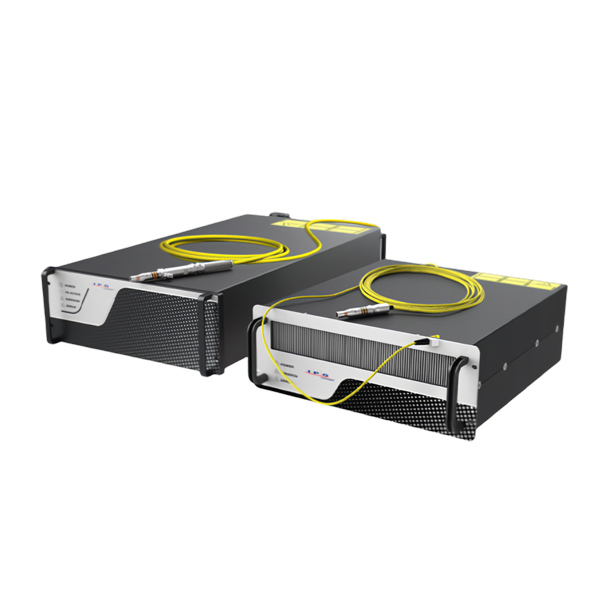

| Laser Brand | IPG/MAX/Raycus | |||

| Average power consumption of the entire machine | 4.5KW | 6KW | 9KW | 16KW |

| Environmental requirements | temperature:10-40℃; humidity:10~85% | |||

| X/Y/Z-axis positioning accuracy | ±0.03mm | |||

| X/Y/Z axis travel | 400*300*200mm (Customisable) | |||

| Working Power Supply | AC 220V 50/60HZ | AC 380V 50/60HZ | ||

| Equipment dimensions and weight | 1200*1000*19500mm 450KG(Customisable) | |||

| Remarks | Any functionality can be customised to meet the product’s welding requirements. | |||