Laser burring process, in layman’s terms, is the surface of the object through the laser burning treatment into a rougher state, and then coated with glue or polyurethane, to enhance the adhesion of the surface, usually used in the discharge of electronic products burring treatment, new energy, aluminium shell batteries, such as the surface of the surface of the burring treatment.

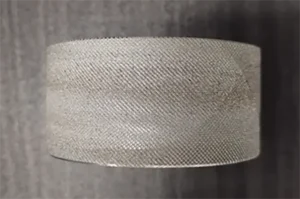

Today, we received a sample from a customer, the roller of escalator, which needs to be treated with laser burring on the surface, and then the surface is filled with polyurethane to enhance the adsorption of polyurethane, the product is as follows.

Customers require a certain depth of the surface of the product after laser burring, our engineers recommend the use of 1000W single-mode pulsed laser sampling test, with 360 ° rotating device synchronised, due to the laser burring dust is large, but also equipped with a purifier for dust extraction, the specific sampling process, please see the following video 。

Test data

| Model | CM-1000 |

| laser power | 1000W |

| sample time | 15s |

| Cooling method | water cooling |

| power supply | 220V 50/60HZ |