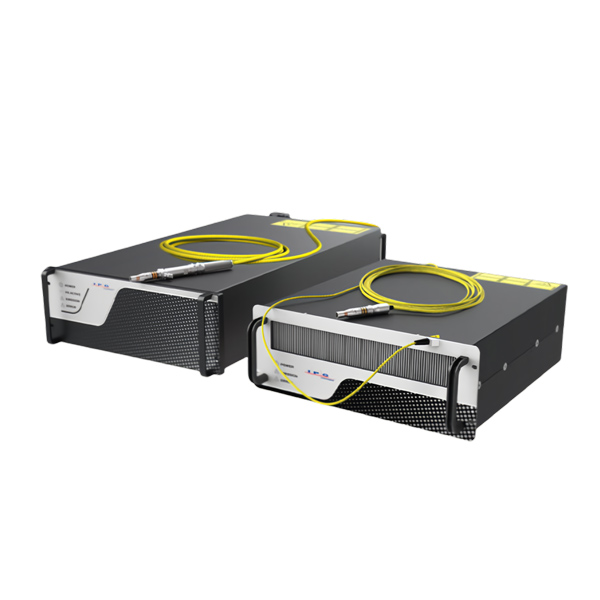

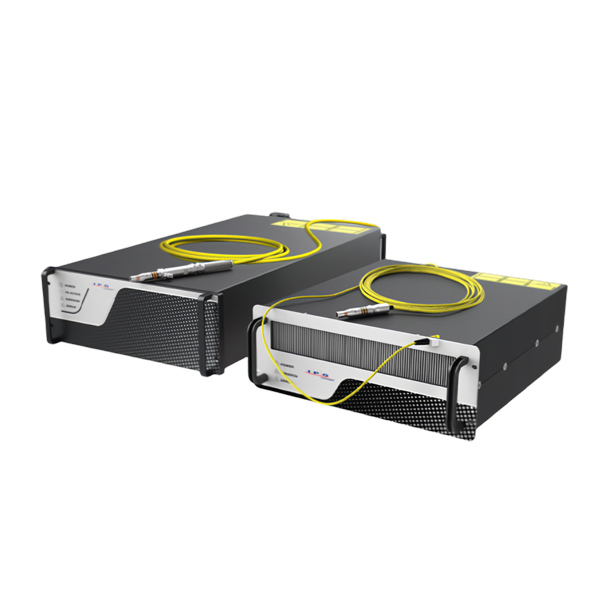

QCW Dual-Head High-Speed Galvanometer Scanning Laser Spot Welder

Dual-head high-speed scanning galvo laser spot welder utilises a QCW fibre laser. Through the welding control system, both scanning galvos emit light simultaneously to weld products, significantly enhancing production efficiency. Widely employed for welding Type-C connectors, precision communication components, and medical devices, it is designed for use with automated production equipment.

Products Categories

Get A Free Quote

Features of the QCW Dual-Head Laser Spot Welder

- Employing two QCW fibre lasers, two high-speed scanning galvanometer lenses, and two control systems, with simultaneous beam emission.

- The QCW laser offers the advantages of minimal heat-affected zone during welding, stable pulse energy, rapid emission frequency, and high peak energy.

- High electro-optical conversion efficiency, excellent beam quality, and maintenance-free operation make it the perfect replacement for lamp-pumped YAG lasers.

- Employing a high-speed scanning vibrating lens to perform spot welding on solder joints within a defined area significantly enhances production efficiency.

- The system is simple to operate, with any welding waveform adjustable, and the energy for each weld point can be set individually.

- The machine features high modular integration and is convenient for automated use, supporting custom configurations such as dual, triple, or quad scanning vibration lens setups.

- Support for machine customisation (such as Logo, cabinet structures, welding capabilities, vision-based gripping, etc.)

QCW Dual-Head Laser Spot Welder Specification List

| Machine Model | CM-QCW150 | CM-QCW300 | CM-QCW450 | CM-QCW750 | |

| Laser Wavelength | 1070nm | ||||

| Output Average Power | 150W | 300W | 450W | 750W | |

| Peak power | 1.5KW | 3KW | 4.5KW | 7.5KW | |

| Maximum Pulse Energy | 15J | 30J | 45J | 75J | |

| Fibre length | 5m(Customisable) | ||||

| Power adjustment range | 10-100% | ||||

| Laser Frequency Modulation | 10KHZ | ||||

| Laser Operating Mode | Pulse/Continuous | ||||

| Power Stability | ±1% | ||||

| Cooling Method | Air-cooled | Water-cooled | |||

| Positioning method | Red light indicator | ||||

| Average power consumption of the entire unit | 2KW | 3.2KW | 4KW | 7KW | |

| Welding material | Stainless steel, copper, aluminium alloy, nickel-plated copper and other metallic materials | ||||

| Laser Brand | IPG/MAX/ Other | ||||

| Environmental Requirements | Temperature: 10-40°C; Humidity: 10-85% | ||||

| Operating power supply | AC 220V 50/60HZ | AC 380V 50/60HZ | |||

| Equipment Dimensions and Weight | 540*1040*1100mm 160KG(Customisable)Customisable | ||||

| Remarks | 1、Can be equipped with a visual CCD capture device to enhance product welding precision.

2、Depending on the product’s welding requirements, either a galvanometer scanning head for spot welding or a welding head for spot welding may be employed. |

||||