TAYTOOLS 12000W High-Power Intelligent Laser Cutting Head

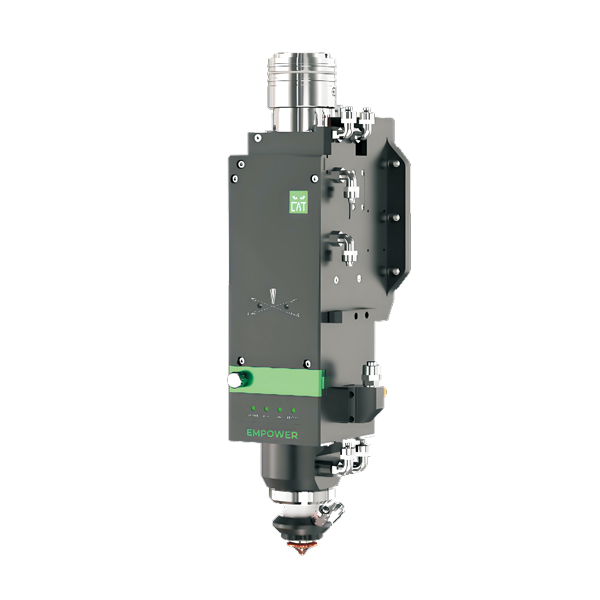

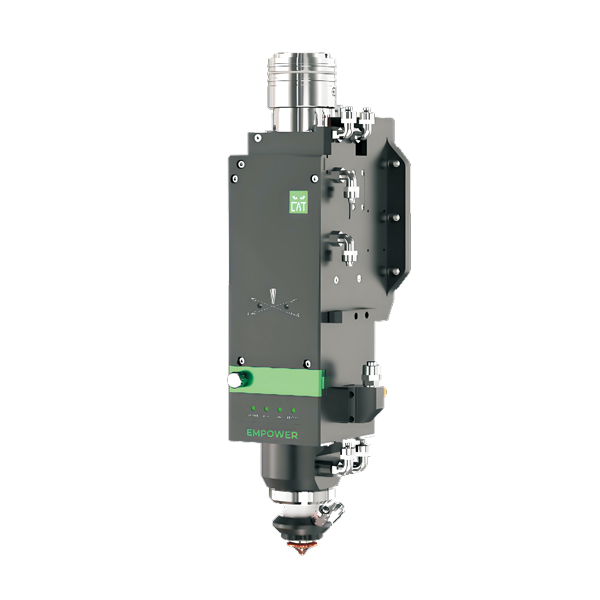

The BS12K-CAT is a high-power intelligent cutting head with a power rating of 12kW. It supports analogue/pulse focusing units or EtherCAT bus communication and bus control focusing units. The product is equipped with multiple fibre optic interfaces, including QBH, QD, Q+, and LOE, and is compatible with various mainstream lasers. It has built-in intelligent sensors and can read and monitor data in real time on mobile terminals and CNC systems via a wireless network.

Products Categories

Get A Free Quote

Product Features

- Multiple protective lenses — 4 sets of protective lenses extend lens life and multiple protection improves the sealing level inside the chamber.

- Flexible control options — supports analogue/pulse control focusing units or EtherCAT bus communication and bus control focusing units. Users can achieve continuous and rapid focus position adjustment through program settings.

- Optimised mechanical/waterway design – simplifies lens installation, reduces maintenance difficulty and costs; anti-collision structure reduces losses caused by misoperation; BS series comes standard with anti-corrosion treatment to prevent water cooling corrosion and water leakage during long-term use.

- Standard air pressure sensor/protective lens temperature monitoring sensor—more accurate gas control and more stable cross-section quality;Air opening protection and foolproof design reduce the probability of lens contamination; One-button intelligent air pressure calibration makes it more convenient and hassle-free to replace nozzles/processes; Real-time monitoring of protective lens temperature during cutting effectively reduces cutting defects caused by protective lens contamination.

- Stray light detection — Standard high-response protective lens stray light detection module effectively prevents lens contamination and cracking.

- Built-in capacitive amplifier — Optional built-in capacitive amplifier model for more precise and stable pitch tracking.

- Perforation detection/process monitoring — Compatible with Jiaqiang CNC systems, with perforation detection and process monitoring as standard features.

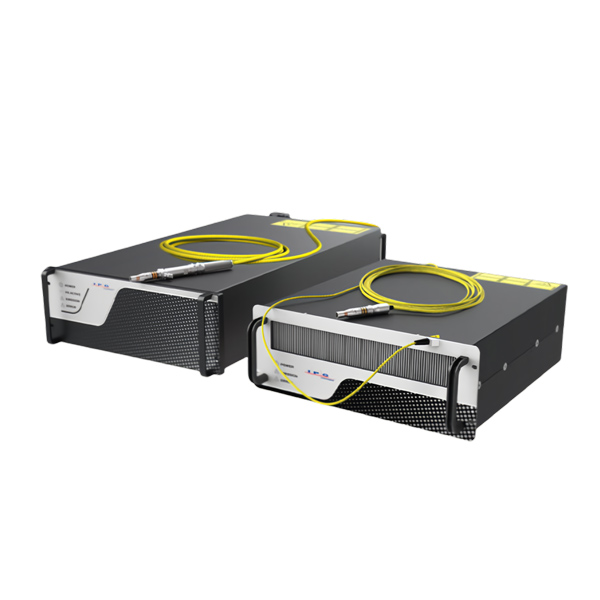

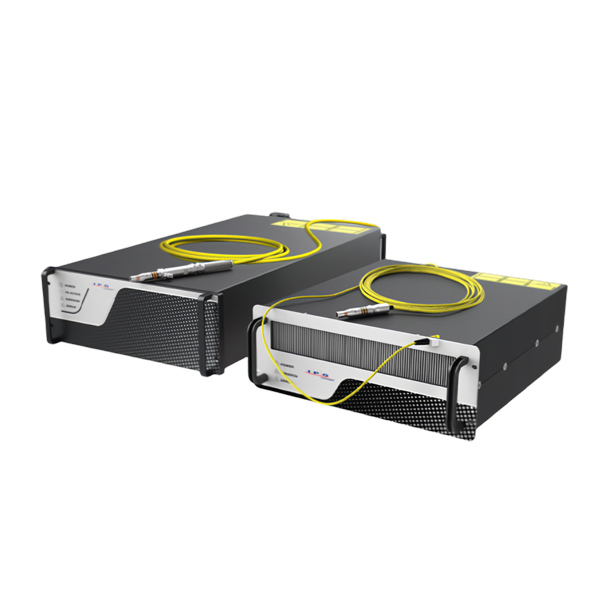

Laser Source Parameters

| Realm | -40mm~+40mm |

| Tempo | ≤200mm/s |

| Accelerations | ≤10m/s² |

| Numerical aperture | 0.14mm |

| Nozzle Rules | Single-layer, double-layer, non-standard |

| Nozzle hole calibre | 1.0mm,1.2m,1.3mm,1.5mm,1..7mm,1.9mm 2.1mm,2.3mm,2.5mm, ,3.5mm, 4.0mm ,5.0mm,7mm |

| Auxiliary gas pressure | ≤30bar |

| Weights | ~8.2kg |

| Accurate | 0.01mm |